Which 3d printing filaments should you use? And when? Discover when to use PLA, PETG and ABS with this guide.

Table of Contents

Introduction

When we talk about starting to make parts with FDM 3D printers, we typically have three main options: PLA, PETG, and ABS.

Indeed, there are more, such as Nylon, TPU, and various composites, but these are less used and are for very specific things.

Within the choice of these three filaments, there often exists a strong confusion about which one should be used for each project.

This leads to seeing parts melted by heat, destroyed by chemicals, and/or broken due to low resistance.

This is due to a lack of knowledge about the use of each material, as everything has its moment and specific situation.

As a general rule, we can make a very simple distinction, some quick rules to select which filament to use.

- PLA: Aesthetic items, rapid prototyping, no stress.

- PETG: Parts that need some elasticity, resistance to moisture and chemicals.

- ABS: Parts that require heat resistance and strength.

However, this brief distinction is often not enough, especially if the reasons behind each choice are not understood.

Let’s take a look at what each filament is about, so you can make the most of your 3D Printer.

All about PLA

Polylactic Acid (PLA) is possibly the filament that needs no introduction if you’ve already printed your first pieces.

It’s a biodegradable filament, since it’s usually made using sugarcane.

Typically, everyone starts with it, as it’s the easiest to print. You only need an extruder temperature of between 180°C and 220°C.

A heated bed isn’t necessary, though it’s recommended.

Among all filaments, we can say that PLA is both the most satisfying and problematic, let me explain.

Aesthetically, it’s a very pleasing filament, easy to print, and available in a wide range of colors.

However, it tends to present several problems.

Its structure is crystalline, making it extremely rigid and therefore less resistant to mechanical stress.

It has no heat resistance; its glass transition temperature is very low. If you leave it inside a car in summer, it will tend to melt extremely easily.

It’s biodegradable, and ultraviolet radiation and humidity tend to mercilessly destroy this filament.

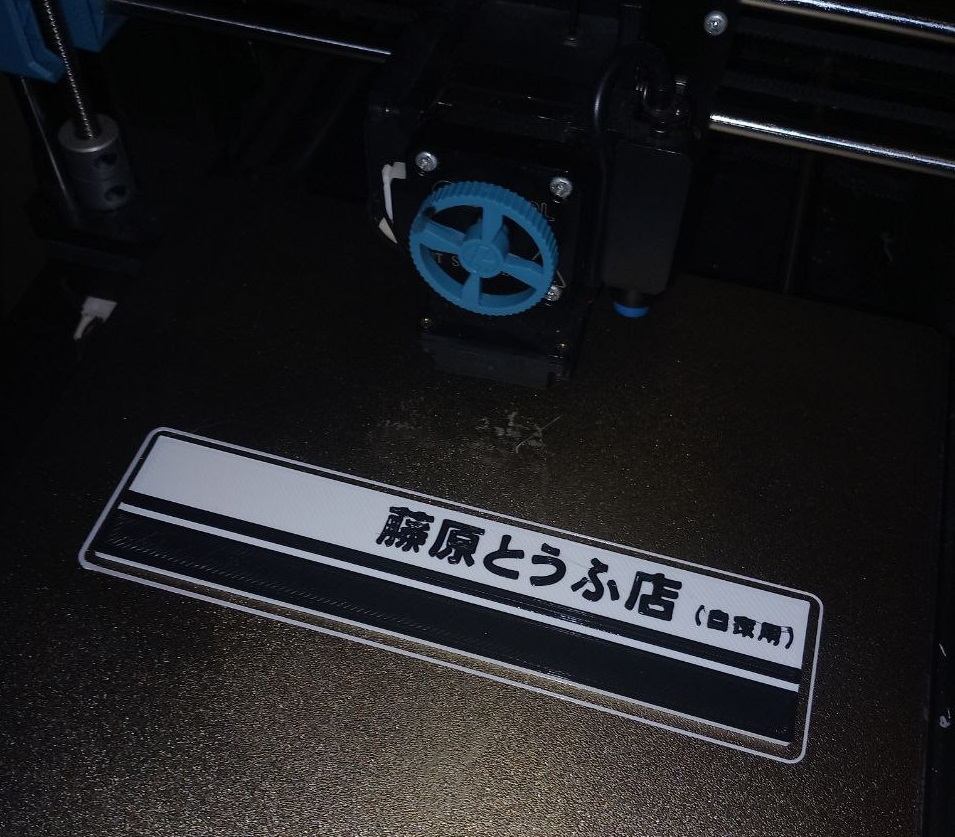

When should you use PLA? Non-functional prototypes, decorative pieces, simple toys.

PLA is ideal for printing chess pieces, toys, keychains, or for making a simple mobile phone holder for your wall.

Of all the existing filaments, we can say it has the most limitations.

However, these are often polarizing.

Many people will tell you it’s suitable for everything, and others for nothing. I’ve seen both “apostles” of PLA and detractors.

Everything has its use. If your piece doesn’t have to endure the elements or mechanical stresses, you can use PLA without problems. You just need to know its limits.

If your piece exceeds the limits of PLA, it’s time to move on to PETG.

PETG – The “go to” of filaments

The use of PETG is the natural evolutionary step for a maker, solving the problems of PLA without adding too much difficulty in printing.

I often refer to it as the “go-to”, the standard filament, suitable for almost everything and easy to print.

PETG is a modified copolymer of PET (the same material used in plastic bottles), but with the addition of glycol to improve its printing properties.

Being based on PET, you can imagine that it shares a slight similarity with bottles, being slightly flexible, so it withstands impacts and traction well.

It requires a higher printing temperature than PLA, as its glass transition temperature is higher, and it also requires a heated bed.

Typically, the extruder is set between 220°C and 240°C, and the bed close to 80°C.

Despite sounding counterintuitive due to the need for higher temperature, it tends to offer perfect layer fusion and exceptional bed adhesion, especially when using a PEI bed.

PETG allows us to create functional and outdoor applications. It resists moisture, ultraviolet radiation, and chemicals remarkably well.

Also, having a higher glass transition temperature, it can withstand more heat.

PETG filaments are great for functional parts that will undergo stress and/or be exposed to outdoors.

Moreover, aesthetically, it can produce wonderful results.

This filament mainly has two drawbacks: the price is higher than ABS and PLA, and for intensive uses, it does not perform as well as ABS.

That’s why for purely aesthetic pieces, where PETG is not necessary, many people opt to print in PLA.

When should you use PETG filament? For parts that require moderate effort and will be exposed to the outdoors.

In the example mentioned above, due to its elasticity and indoor use, it was used as an adapter from a real steering wheel to a PC one.

The piece withstands stress without problems.

ABS – The industrial standard

Virtually all plastic manufactured in industrial processes is made of ABS.

The vents in your car, your child’s favorite toys, the comb in your bathroom.

Why? It’s cheap and durable.

It has greater impact and temperature resistance than PETG and PLA, so it can be used in any application.

For example, it’s the only material that can withstand the heat emitted by a car’s heater.

Additionally, aesthetically, it tends to look the best, as the layers are barely visible, and you can sand and paint it easily if necessary.

It tends to be susceptible to moisture, but painting the final pieces usually solves all those problems.

It’s not a plastic too commonly used due to its complexity in printing; it needs a controlled temperature and a low speed to ensure that the layers adhere well.

When should you use ABS? For extreme heat resistance, and uses where it is prone to excessive stress. For example, automotive uses.

All filaments are useful

The key takeaway from this article is to understand that all filaments have their time and specific use.

I’ve heard many complaints about 3D printing regarding the low durability of the pieces.

I remember when I first made vents for my car and they melted within 5 minutes of using the heater.

Why? Because I used PLA when I should have used ABS.

If you print with the correct filaments, these issues won’t occur, and you’ll have parts that last as long as those made with molds.

Does it make sense to struggle with ABS and its printing difficulty for chess pieces? No, you would use PETG, or if you want to paint and treat the pieces, PLA.

Each filament has its moment.

I hope this article has been helpful, and remember that you can learn more about 3D Printing on this blog.